Agnostic surface screening solution for high quality flexo print

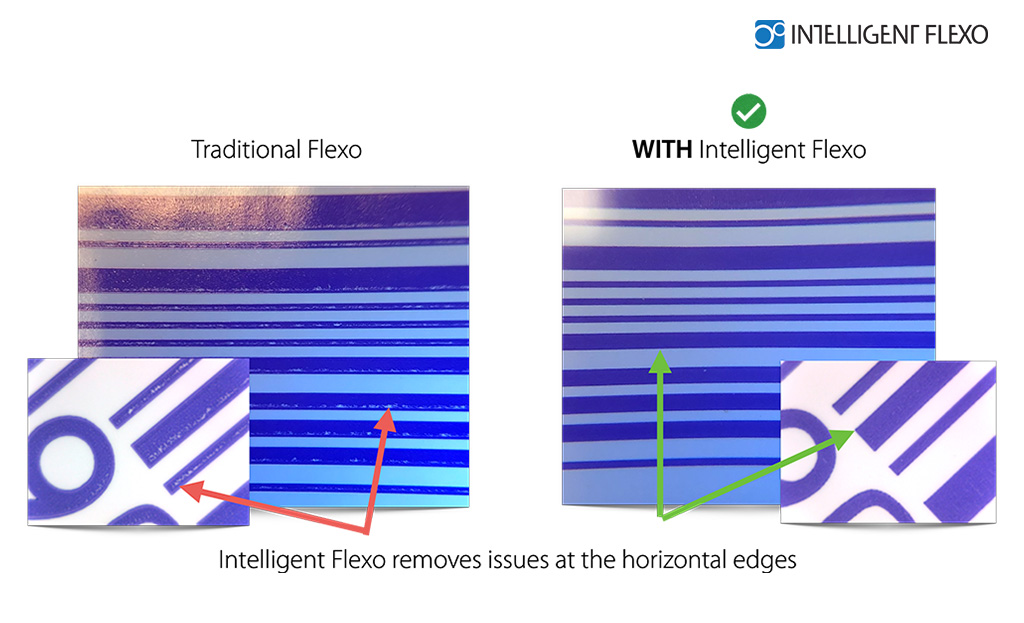

- Improves quality of flexo output by identifying problem areas needing intervention before printing on the press

- Operates independently of RIP vendor, plate supplier or CTP manufacturer, and ink type

- Suitable for labels, flexibles, folding carton, and corrugated packaging

- Eliminate common flexo problems such as trailing-edge void, dot gain, ink spread, and poor ink laydown

- Automated marking of plates with non-erasable and non-printable marks

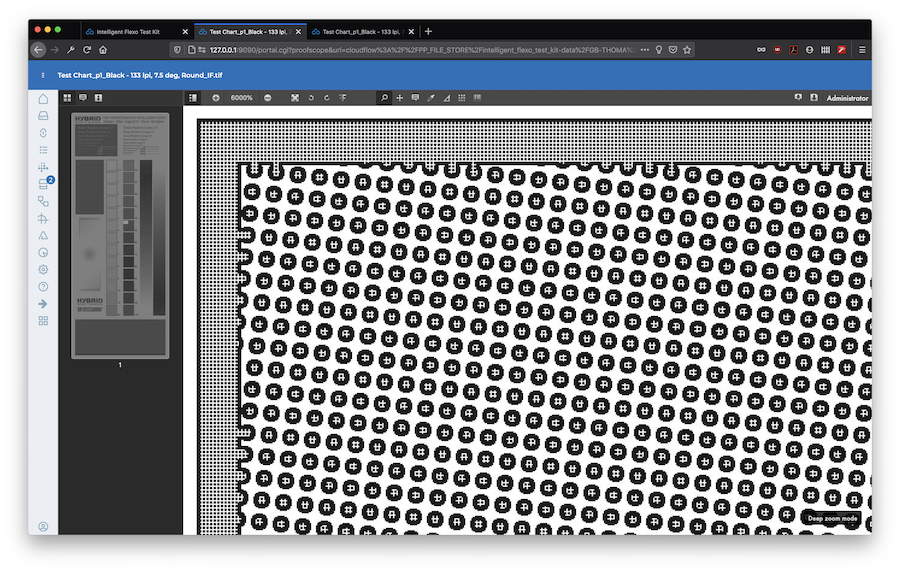

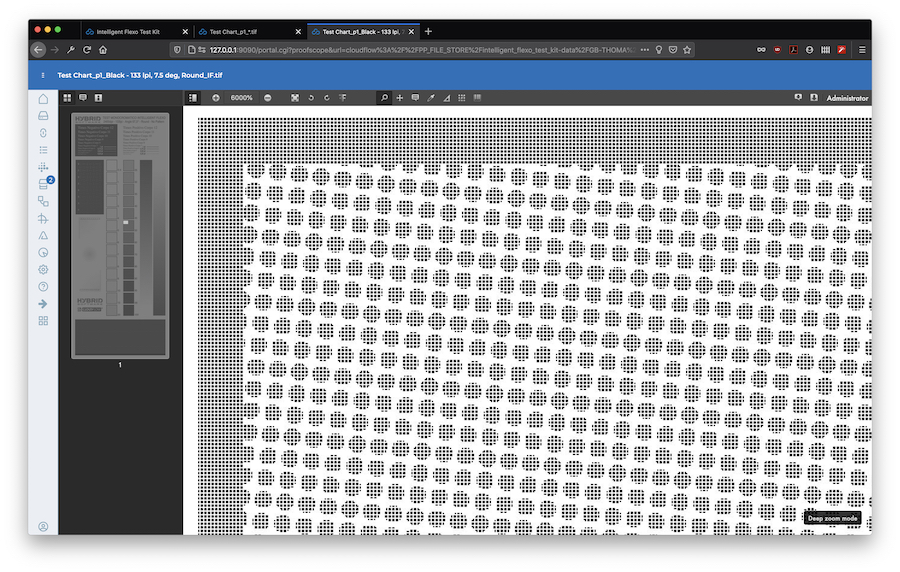

- Lower ink consumption, increased print quality of flat tints, vignettes, barcodes and fine text

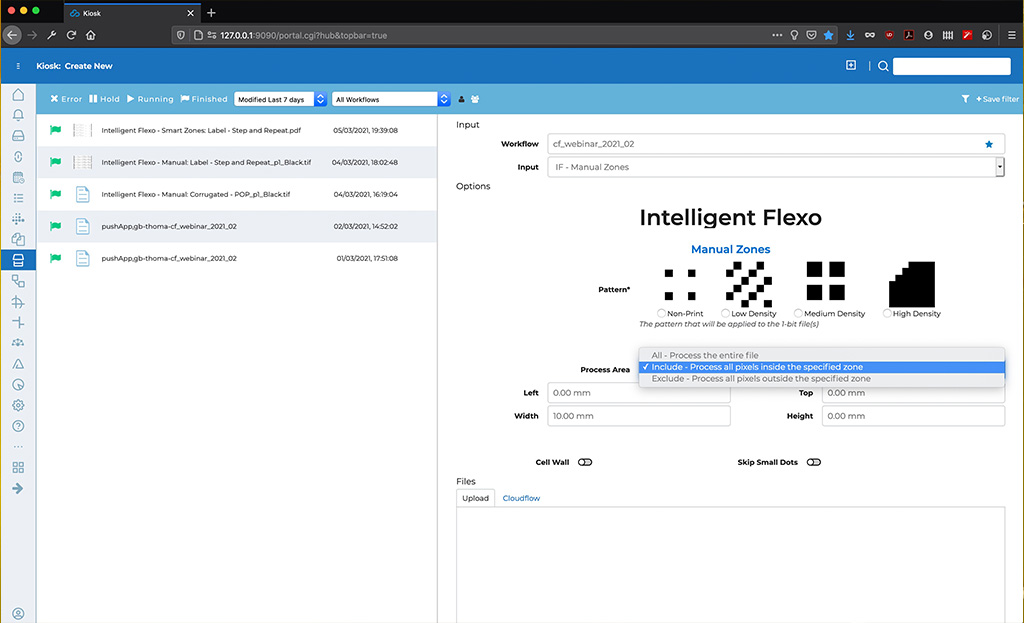

- Highly adaptable and integrated workflow solution

- Saves time and valuable resources